For us, failure is not an option

Let’s get a bit nerdy about corrosion, shall we…

Thiobaccillus concretivorus and Thiobaccillus ferrooxidans are tiny bacteria that decompose sewage and form hydrogen sulfide gas (H2S).

When combined with moist air, the gas forms sulphuric acid (H2SO4) which is highly corrosive to materials like concrete, steel, and cast iron and can cause significant damage over time. Corrosion is also a major problem in seawater applications, where the contained sodium chloride eats away at e.g. metals, and causes them to fall apart.

With GRP products, the situation is quite different. Plastics are inherently more robust than both concrete and metals in acidic environments.

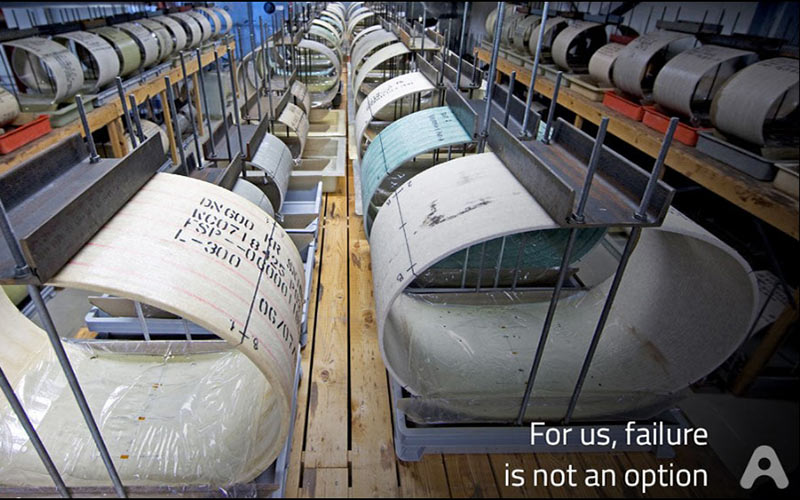

To prove this, we literally put our pipes to the acid test: Several pipe samples are exposed to sulphuric acid (H2SO4) for a considerable time while being subjected to artificially high tensile strains (that’s what you see in the photo).

The idea is to simulate the chemical conditions in aggressive sewage, but under an excessive strain in order to cause failure within a reasonable time frame. Turns out Amiblu GRP pipes last for generations.